METAL COATING

Zinc coating low acid (in drums or on devices)

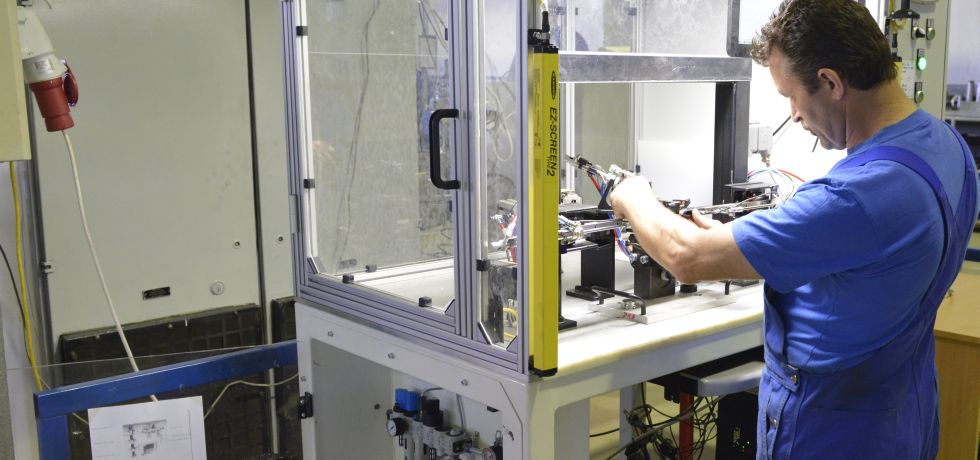

Automatic equipment for electrochemical zinc plated (MANZ)

Electrochemical zinc plated low acid based on chlorides (zinc chloride; potassium chloride; advanced system with gloss agents).

The surface preparation before zinc plated is done by chemical degreasing; electrochemical degreasing; acid pickling.

Zinc electroplating itself is accomplished by immersion of the parts in the bath of electrolyte for 30 ÷ 120 min, according to the thickness of zinc required. Thickness obtained 5-20 µm.

Passivation of zinc coating in solution based on trivalent chromium (iridescent white passivation).

The coating gives corrosion resistance according to SR EN ISO 2081.

To ensure special corrosion resistance requirements (salt spray test according to ISO 9227: 400 – 600 hours rust less) are applied additional coatings based on polymers.

Alkaline Zn-Ni alloy electroplating line for steel, with passivation and post-treatment, in racks and barrels

- min. 8 µm thickness layer

- Salt spray test cf. ISO 9227:

- 480h without red rust

- 720h without red rust (passivation and sealer/top coat)

Types of parts: machined parts; stamped parts; bushings and pipes; small coil springs (tension, torsion , compression); rods (max. length 150 mm); bolts

Phosphating

Phosphating mechanized installation – made in Compa

Phosphating with zinc salt, phosphating with manganese salts

Phosphating is performed by immersing the parts arranged in baskets/drums/devices in a flow that includes degreasing, pickling, phosphating, neutralizing conservation in emulsifiable or not emulsifiable oil

Phosphating installation – VBH – producer Eisenmann AG

The method consists in pickling the parts before the painting process, applying in the same time the phosphate coat on 1 – 2 µm to ensure better adhesion of paint on the piece.

– The waste water resulting from this process is treated and neutralized in the own installation so that wastewaters parameters to meet the legal.

Browning is performed on the mechanized installation for browning, by immersing the parts (arranged in baskets) in a flow that includes:

-degreasing, pickling, browning; oil preservation.

PAINTING

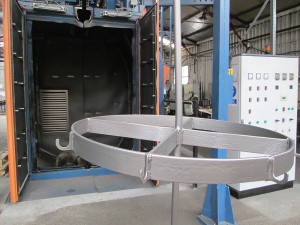

The painting installation with liquid paint / powder paint

- Transport of the parts: tractor chain conveyor

- Maximum dimensions of the suspended assembly: (LxlxH) 2000 x 1000 x 1500

- Maximum weight / suspended assembly: 500 kg

- Part type: metal structure

- Paint type/Method of application:

- Paint diluent based / manual spray tip airmix

- Powder paint/manual spray in electrostatic field

- Preparing the surfaces of parts before painting is performed by:

- Shot blasting

- Phospho-degreasing

The installation of powder paint coating

- Transport of the parts: tractor chain conveyor

- Maximum dimensions of the suspended assembly: (LxlxH) 1500 x 1000 x 300

- Maximum weight / suspended assembly: 40 kg

- Part type

- Paint type/Method of application: Robot painting sprayers type OPTIGUN 2-A(X) and manual paint.

- POLYMERIZATION powder paint- gas furnace.

KTL painting (priming) KTLL

- Producer Eisenmann AG

- Covering (painting, priming) the parts for high corrosion protection.

- The west water is treated and discharged at the rate imposed by environmental legislation.

The installation of electrostatic painting

- Producer: Eisenmann-Wagner

- Ensure a uniform final coat and UV protection.

- It is one of most modern facilities in terms of quality and consumer of paint.

- Dry filter system that is provided makes it more environmentally friendly.