The research and development activity, as a medium and long term component of COMPA’s strategy, benefited from significant increase of resource allocation in the last years. In general, the engineering department’s efforts are directed towards the performance of the processes: quality, productivity, cost.

Technological processes developed and implemented successfully in production:

- Automatization through robots of processing cells for the manufacturing of blank injectors’ bodies

- Prototyping cell for turbocharger components.

- EDM process extension of components for dies, molds, devices and 5-axis machining process extension

- Extending of tempering treatment with controlled atmosphere type ENDO

- Improvement of the phosphatising process

- Improving of the processes for mechanical-welded parts: bending, punching and high speed cutting, CNC machining, mechanical hardening, flow painting

- Precision punching

- Integration of primary processes: cutting, forging, rough machining

- Improving of electrostatic painting for wiper components

- Expanding of production capacity: semi-automatic assembly lines with flow control and POKA-YOKE system, high productivity equipment in 2,3 and 5 axes, deep drill machines, coiling spring machines.

COMPA is registered in the Register of Potential Contractors

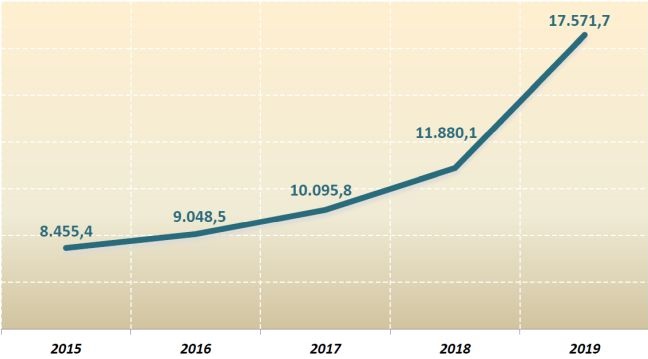

Research and development outgoing (thousand lei)