Processing by cold pressing of parts is done by simple or combined operations.

- – Simple cold pressing operations are performed both on manual and automatic presses, and from these result:

- cut flat pieces, drilled and shaped, such as spring plates, intake plates, adjustment washers used to adjust hydraulic forces in embedded or slide system;

- pieces made by volumetric deformation, precision parts used in hydraulics and pneumatics for achieving strength and tightness as well as clamping pneumatic devices Hayon type on vehicles;

- bent, stamped, perforated, deformed , embossed, rolled, calibrated, marked parts used for covers, protections, forks, spacers, levers, discs;

- deep drawn parts.

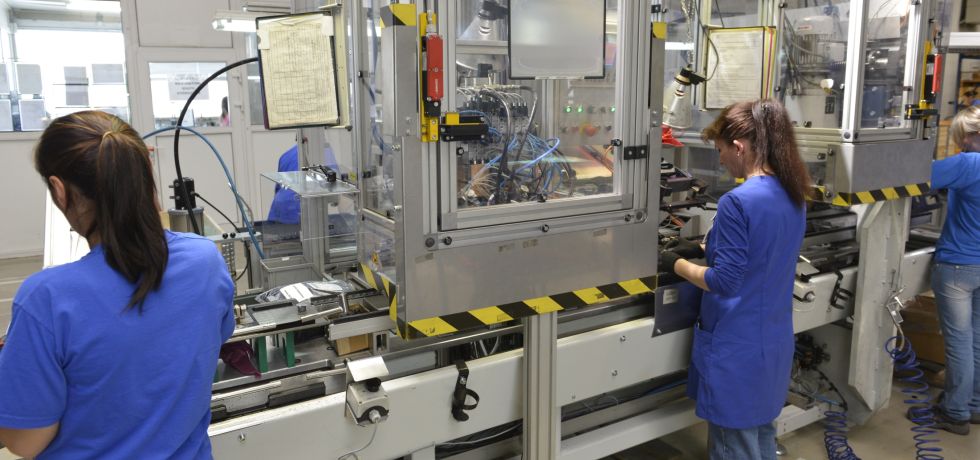

- – Combined operations include:

- simultaneous operations on manual and automatic presses;

- successive operations are performed on successive dies on automatic presses. Parts made on automatic presses are parts like supports, covers, flaps, washers, discs, disc springs, etc.

Materials used::

- plates with thicknesses between 0.4 ÷ 6 mm different sizes and qualities.

- strip thicknesses between 0.1 ÷ 4 mm, with maximum width of 800 mm.

Equipment::

- 4 hydraulic presses 160 ÷ 250 tf

- 5 automatic presses 200 ÷ 250 tf

- 5 eccentric presses 250 ÷ 400 tf

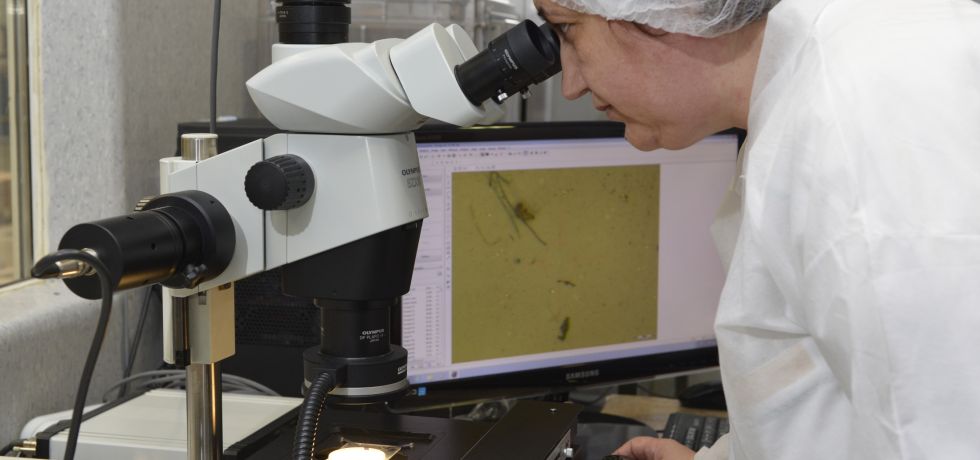

After stamping additional operations can be performed, such as: deburring by vibro-finish and belt grinding, washing, conservation, MIG / MAG welding, pressure welding, turning.