These requirements are achieved by extensive use of digital dimensional measuring instruments from the simplest (calipers , micrometers, pneumatic devices) to the more complex such as:

- Digital measuring columns (measurement scale)

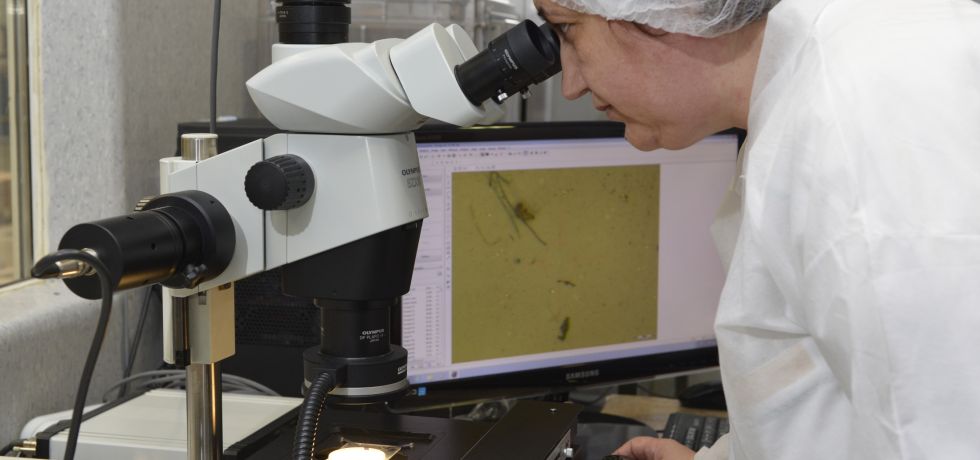

- Automatic optical scanners (fast measurement size, concentric run-out and coaxiality for revolution parts )

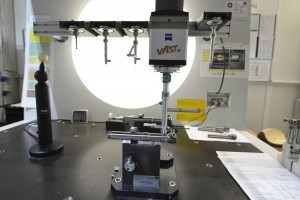

- Profile measurements and digital roughness measurement ( 2D – ray profiles , angles, distances and roughness in all standard systems )

- Digital form-tester ( deviation form – flatness, circularity, cylindricity)

- 2 portable manual CMM ( 3D measurement software for parts and large welded assemblies) – 2 pcs

- CMM – automated (3D measurement by CNC programs measuring dimensional deviations, shape, position) – 11 pcs.

- Automatic CMM specialized in measuring specific geometric deviations for gears

- laser scanner to assess deviations from flatness and surface imperfections <3µ