Compa has the latest and most advanced technologies of machining, which constitute a technical platform with more than 400 CNC machines.

Turning

Compa produces turned parts on CNC machines with 2 or 3 axes (with diameter up to 150mm) and clamping in chucks or in specific fasteners.

-CNC lathe 3 axis Gildemeister DMG CTX 310 Ecoline

– processing machines with bar feeding (diameter 15, 25, 40 mm). Lathes with one clamping chuck and a turret (Mazak, Swing)

– lathes with two clamping chucks and two turrets (Emco, Mazak multiplex 6200 II)

– multi-axes lathes with 6 clamping chucks (Gildemeister)

– vertical lathes with NC IVS200M

Milling, drilling, reaming, threading

Compa has CNC machining centers with 3, 4 and 5 axe with horizontal or vertical processing. Thus milling, drilling, reaming, tapping, profiles machining can be achieved (Mazak machines, Spinner, Chiron, Okuma, DMG Gildemeister).

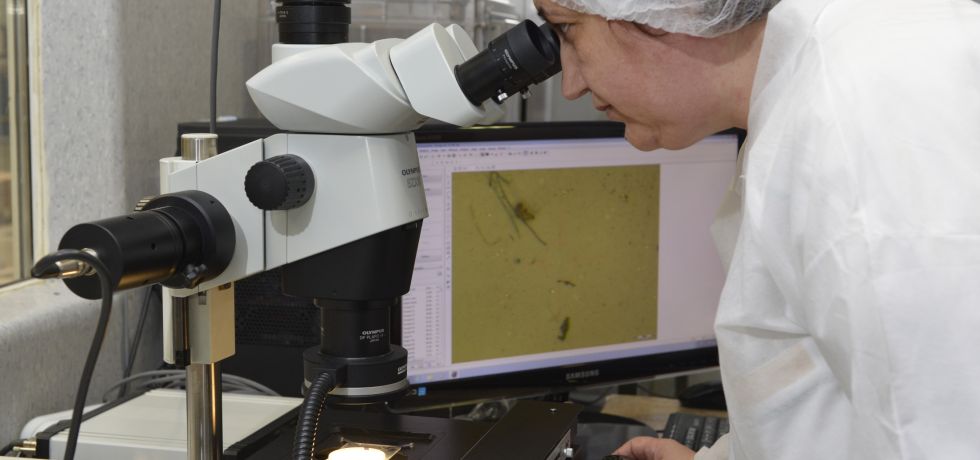

Precision of the machines and equipment with the latest tools, adapted to each type of processing, ensures a high level of quality of machined parts. This allows us to process parts with micron precision and roughness under Ra 0,8. To check these parts we use Zeiss 3D control machines, the only ones that can check parts with micron tolerances.

The stability of our processes provides a level of process capability higher than 2 at process homologation (PPAP) and over 1,67 in series production.

deep drilling – drilling length 100-150 mm and diameter between 1,6 – 5,5 mm (Mollar, Rene, Clemont, TBT)

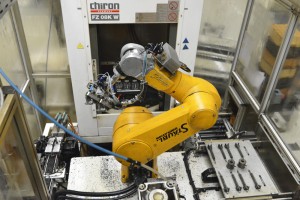

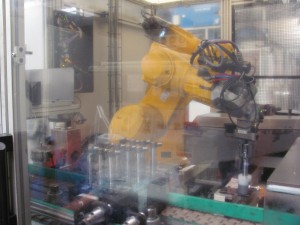

drilling and installation – robotic cell.

flat broaching (20 to) – robotic cell – feeding/ discharge parts+ deburring by brushing

gears toothing – max. mode 3 (Gleason-Pfauter)

Also on special gear cutting machines Gleason Pfauter toothing of the parts after heat treatment is done in order to eliminate deformations and make precise teeth.

Grinding

Circular grinding machine (Tachella, Studer)

Front grinding machines (Supfina)

The level of dimensional precision at grinding is in terms of microns, as well as parts form accuracy (circularity, cylindricity, flatness) and in terms of roughness, by adapting cutting conditions and specific tools to each type of processing parts with Ra values below 0, 1 can be achieved.

Deburring

Deburring of parts is done by various methods

- brush deburring in robot cell (STEA)

- deburring IN oil bath with oil jet high pressure – robotic operation,

- electrochemical deburring-type ECM

Grooving / Threading

Compa has equipment for making grooved and threaded parts by cold plastic deformation (rolling) on machines Profirol.

Sharpening of cutting tools

As Compa specializes in metal cutting, it has a workshop specialized in sharpening cutting tools – on tool re-sharpening machines Walter and optical equipment specialized in checking and presetting tools.